| Author |  Topic Topic  |

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 20 May 2020 : 05:53:15 Posted - 20 May 2020 : 05:53:15

| quote:

Originally posted by melle

I found some formulas for injector sizing here: https://www.rcfuelinjection.com/Technical (they're also in the book I linked). I've made my own calculator in Excel based on the formulas so I could play around with the data of the injectors I have, in units I understand.

I reckon I can get about 90HP out of a high compression 1.7 V4 without spending money on a "hot" cam and other trick parts.

- Number of cylinders 4

- BSFC (Brake-Specific Fuel Consumption) 0.5

- HP 90

- Duty cycle 80%

- Injector cc/min 148

The 2.9 injectors flow 147cc/min at the prescribed 2.7 bar fuel pressure and a safe duty cycle of 80%, so that should be close enough. If not, I could try a set of Fiesta/ Escort ones I also have, which do just under 200cc/min at the same pressure.

www.saabv4.com

At least 156cc/min Bosch EV6 injectors work well at 3bar with 1.5 engine. I think 200cc/min injectors would not be too large at least when using sequential injection where injection pulse is injected once in a engine cycle. If injectors have too high flow rate then injector opening time at idle is too short for injector and adjusting of the idle fuel amount is inaccurate.

Another thing about the injectors is that old injectors get dirty and those should be cleaned to ensure equal operation between individual injectors. The price difference between the new Bosch EV14 injectors and cleaning of the old ones was not much. So I have now a new set of EV14 injectors waiting for the plenum type intake manifold. Those were under 100/4pcs. With EV14 type of injectors the spray pattern is wider and better for fuel-air mixing when compared to EV6 and much better when compared to EV1 type of injectors. There are some comparison videos in youtube between injector series and there is a difference. In theory you should at least get better fuel economy and idle with EV6/EV14 injectors when compared to EV1.

|  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 20 May 2020 : 14:37:38 Posted - 20 May 2020 : 14:37:38

| I'm not convinced of the benefits of sequential injection on a standard V4, it may be worth it on a more performance-oriented engine though. It should be easy enough to upgrade with Speeduino, which is set up for two crank/ cam sensors. The injectors in the V6 manifold sit under an angle, and I can't use EV6 or EV14 injectors if I want to keep the (shortened) V6 fuel rail, because they're a fair bit taller. I'll try the V6 ones first, and I also have two sets of brand new 214cc/min EV1 injectors in case they don't flow enough. Here's a very useful spreadsheet with details of hundreds of Bosch EFI injectors: www.usrallyteam.com/content/products/injector/Bosch_Injector_data.xls

I've invested in a 4l ultrasonic cleaner about ten years ago, money well spent if you ask me, and I've just bought a cheap injector tester. I've cleaned 12 injectors and a TB this morning, haven't tested the injectors yet. I bought rebuild kits from Brands Hatch Performance: https://www.brandshatchperformance.co.uk/products/weber-bosch-injector-refurb-6-cylinder-kit?_pos=21&_sid=5a77c7a05&_ss=r (they also do kits of 4, if you don't need anything else they're cheaper on eBay due to postage). Making junk work is part of the fun for me!

I've soldered most of the Speeduino kit, but annoyingly a few parts were missing so I can't play with it yet. Hope the last bits get here tomorrow so I can finish it.

Not sure what K-Jet injectors to use for the other engine. I have Saab 900 and Ford 2.8 V6 ones, but they're both rather long, and Golf ones that are a fair bit shorter. I have no idea about flow rates though, would be grateful if anyone could point me towards an overview like the EFI injector one linked above. I have a 2.8 V6 K-Jet manifold I can copy the angles from if I'm using 900 or Ford V6 injectors, which have the same dimensions.

900:

Golf:

Looking forward to seeing pics of your plenum manifold AnttiK!

www.saabv4.com |  |

|

Borstlap

V4 Fanatic

Norway

334 Posts |  Posted - 20 May 2020 : 16:25:28 Posted - 20 May 2020 : 16:25:28

| Why would you need a cam sensor? When you have a crank sensor with (a) missing tooth/teeth the ECU knows the position of the engine and so also when to activate an injector.

Alex |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 20 May 2020 : 16:49:18 Posted - 20 May 2020 : 16:49:18

| For sequential injection you need a cam sensor too.

EDIT: I just realised that was not the most helpful reply. Since the cam turns at half the crank speed, the crank sensor can't tell if a cylinder is at the compression or exhaust stroke, that's why a cam sensor is needed as well. Crank sensor only would result in "wasted squirt" I guess, but I'm not exactly sure why you can't just use a cam sensor only.

www.saabv4.com |

Edited by - melle on 20 May 2020 17:08:37 |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 20 May 2020 : 17:09:46 Posted - 20 May 2020 : 17:09:46

| In four stroke engine crankshaft turns two revolutions in one engine cycle and the intake valve is open once in two crankshaft revolutions in each cylinder. With crankshaft sensor ecu does not know which cycle is currently ongoing. With camshaft sensor ecu has information which one of the cycles is ongoing at the moment.

I have inspected the sequential injection benefits and actually there is not much benefit to the maximum output power, because with maximum power injector open times are usually longer than intake valve open times so the operation is almost the same with or without sequential injection on maximum power. Benefits of the sequential are smoother idle, lower emissions, better fuel economy in partial throttle and faster throttle response. And based on the experience after adding sequential I think those are true.

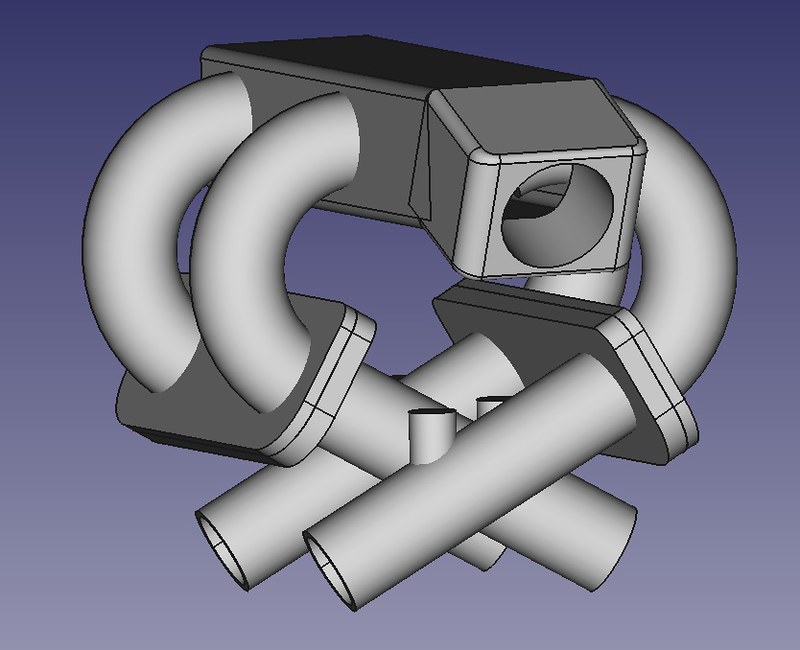

At the moment my plenum type of the manifold looks like this. Intake runners are close to the saab original cross intake manifold, but the inside diameter is probably smaller (34mm). I have looked from the A. Graham Bell books about the intake runner area and about 34mm should be close, when using 42mm intake valve. At the moment I am using 39.5mm intake valve, but maybe in the future I'll be using 42mm valve. Plans are to use steel for the upper part of the manifold, because it is easier to weld and to try different kind of plenum sizes

And the plan is to make this kind of plenum. It should fit under the bonnet, but it will be quite tight

There is about 22cm room between manifold fixing bolt -plane between 2. cylinder and distributor, so I think Melle's modified 2.9 manifold should fit under the bonnet?

|

Edited by - AnttiK on 20 May 2020 17:39:49 |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 20 May 2020 : 17:37:12 Posted - 20 May 2020 : 17:37:12

| quote:

Originally posted by melle

The injectors in the V6 manifold sit under an angle, and I can't use EV6 or EV14 injectors if I want to keep the (shortened) V6 fuel rail, because they're a fair bit taller.

In 2.9 manifold injector is probably in relatively good angle in relation to intake runner, so it there is not probably much difference between EV1/EV6/EV14. In my present 1 barrel intake manifold injectors are almost ortogonal to intake runner, so in that case EV6 might work a bit better. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 20 May 2020 : 18:08:22 Posted - 20 May 2020 : 18:08:22

| Thanks for the measurements, very useful, looks like my plenum will fit easily. Nice work on the manifold. I'm also set up for MIG welding aluminium, but I agree it's a pain in the arse. A spool gun should make it a bit easier, but I can't justify buying one and would rather invest in TIG at some point.

I read the Bell and Vizard books years ago, so would have to look up details, but I seem to remember the runner formulas are slightly different for inline and V engines?

www.saabv4.com |

Edited by - melle on 20 May 2020 18:11:41 |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 20 May 2020 : 18:51:18 Posted - 20 May 2020 : 18:51:18

| Actually there are only two formulas for intake runner diameter, which I used from Bell book:

0.81-0.83 x intake valve diameter = runner diameter for round runner

0.67 x intake runner area = intake runner area for rectangular runner

For intake runner length I have used some calculators from web, but there are so many variables in those like inlet valve duration etc, but I think intake runner length close to 35-40cm should give better low end torque. I am not an expert, but I think usually intake runners are short in production car because of space requirements and also production costs, because same manifold must fit to different models.

I do not know if there is a difference between inline and V intake runner calculations. When the ignition events between cylinders are the same in inline-4 and V4; is there then difference between those in runner calculation? |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 20 May 2020 : 20:34:24 Posted - 20 May 2020 : 20:34:24

| I may be misremembering (I'm by no means an expert either!), I'll see if I can find it.

Yes, I agree, runner length is always a compromise, it'll only be "ideal" for a specific purpose, under particular circumstances (hence variable length intakes on some modern engines). I don't care too much about top speed, but I like low rpm torque. Unfortunately, I also like the V4, which isn't the best engine for making a lot of torque at low rpm anyway, and my K-Jet inlet design will perhaps make it worse... 1.7 We'll see.

www.saabv4.com |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 21 May 2020 : 06:37:41 Posted - 21 May 2020 : 06:37:41

| Here is one intake runner calculator and according to it optimum runner length is i.e. about 42.5cm, when rpm is 4000, intake valve duration 280 degrees.

http://www.exx.se/techinfo/runners/runners.html

According to that calculator I would guess that 2.9 manifold is tuned to higher rpm, but anyway it should be much better than stock v4 manifold, where intake runners are much shorter and I think one problem with the stock manifold is that when firing order is 1-3-4-2; 1. and 3. cylinders share partly same intake runner and then intake suction pulses interfere with each other, which leads to uneven air/fuel mix between cylinders. If you look at the 'modern' intake manifolds in V8 carburettor engines there are dividers between the runners.

I think with exhaust manifold it is in principle the same thing. By dual port modification it should be possible make engine run more freely, which might result better fuel economy and also better overall performance. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 21 May 2020 : 22:59:14 Posted - 21 May 2020 : 22:59:14

| Thanks for the link to the calculator, saves me making my own. Will do some calculations later. Just skimmed through the relevant chapter of Bell's Performance Tuning book and I couldn't find anything on design differences between inline and V engine runner design, so I was probably mixing it up in my head with something else.

quote:

Originally posted by AnttiK

According to that calculator I would guess that 2.9 manifold is tuned to higher rpm

Max torque for the 2.9 V6 is 222-233Nm at 3000 rpm, max HP is 107-110 at 5500/5700 rpm depending on type. Pretty poor for such a big engine with EFI and EMS, the 2.0 Saab 900 8V KE-Jet engine (with an inferior injection system and primitive engine management) makes more power (116 HP) at the same rpm, it has its peak torque at considerably higher (3700) rpm though. That being said, the 12V 2.9 V6 is a very smooth engine and they'll pull all day long, the 8V 900i is no match in this respect!

quote:

Originally posted by AnttiK

but anyway it should be much better than stock v4 manifold, where intake runners are much shorter and I think one problem with the stock manifold is that when firing order is 1-3-4-2; 1. and 3. cylinders share partly same intake runner and then intake suction pulses interfere with each other, which leads to uneven air/fuel mix between cylinders.

I agree, this is an issue. The V6 plenum is a split design, so essentially a plenum for each bank, and the firing alternates between the banks. Since the V4's FO is 1-3-4-2, it fires right/left/left/right, so I'll need to remove the baffle in the plenum to avoid charge robbing on the EFI engine. For the K-Jet engine I really want something that bolts onto the existing manifold, so I'll take the manifold design as it is. What I may do, is add a bolt on plenum, and/ or use a 1.5 engine instead of a 1.7, because the shorter throw engine will rev a bit easier. What I'm not going to do, is invest in cams and bigger pistons and valves. I believe it just doesn't make sense for my intended use (rarely >4000rpm, let alone 5500 at which aforementioned upgrades start to provide as I understand it).

quote:

Originally posted by AnttiK

I think with exhaust manifold it is in principle the same thing. By dual port modification it should be possible make engine run more freely, which might result better fuel economy and also better overall performance.

Agree, but too much work for me at the moment. I've ported mine and built my own downpipes, which made a noticeable difference on engine smoothness (may be placebo though, I've never had the car on the rollers).

www.saabv4.com |

Edited by - melle on 21 May 2020 23:04:20 |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 22 May 2020 : 09:01:23 Posted - 22 May 2020 : 09:01:23

| quote:

Max torque for the 2.9 V6 is 222-233Nm at 3000 rpm, max HP is 107-110 at 5500/5700 rpm depending on type. Pretty poor for such a big engine with EFI and EMS, the 2.0 Saab 900 8V KE-Jet engine (with an inferior injection system and primitive engine management) makes more power (116 HP) at the same rpm, it has its peak torque at considerably higher (3700) rpm though. That being said, the 12V 2.9 V6 is a very smooth engine and they'll pull all day long, the 8V 900i is no match in this respect!

In my understanding 2.9 V6 max kiloWatts are around 107-110 not HP, but quite low tuned engine anyway. There is interesting project ongoing in Sweden, where 2.9 cosworth 24v engine cylinder head and some other parts are going to be fitted to a V4. A lot of modifications are to be done.

https://saabklubben.se/forum/amne/saab-96-v4-16v/

quote:

Agree, but too much work for me at the moment. I've ported mine and built my own downpipes, which made a noticeable difference on engine smoothness (may be placebo though, I've never had the car on the rollers).

I looked at your car project thread and your downpipe setup is very similar to mine. The 2-1 collector is almost in the same place and I agree there is noticable difference in engine behaviour. When I installed the 7.2 cam and new downpipe I was surprised on the improvement of engine smoothness and power increase. And I am pretty sure 7.2 cam was not the only reason for this improvement.

My plans for dual port exhaust are also quite far away. Maybe after two years or something, because I want to make one modification at time and drive with it. Exhaust dividing I am going make in this way:

https://saabklubben.se/forum/amne/dubbelblas-3/#post-457813

Sorry for mixing these other things to your injection topic I think modifying the 2.9 intake manifold is a good idea and final result depends how the welding is succeeded. I think modifying the 2.9 intake manifold is a good idea and final result depends how the welding is succeeded. |  |

|

melle

V4 Guru

United Kingdom

3833 Posts |  Posted - 22 May 2020 : 11:25:42 Posted - 22 May 2020 : 11:25:42

| quote:

Originally posted by AnttiK

In my understanding 2.9 V6 max kiloWatts are around 107-110 not HP

I just checked the Sierra Haynes manual and you're right, there was an error in my notes. 145HP is still not great indeed, but I wouldn't be surprised if that could be improved quite a bit, like the standard V4 can be improved, even before spending money. I think Ford Motorsport got about 200HP out of the 12V V6 (although I assume they did spend money to get there!).

That Swedish 16V project looks interesting, but I'm not sure I understand how they're going to do it, so looking forward to reading about their progress.

quote:

Originally posted by AnttiK

And I am pretty sure 7.2 cam was not the only reason for this improvement.

One of the reasons I like V4s so much, is that you can improve them a lot on a very tight budget. Porting is a lot of work, but it costs nothing but time. Apart from the downpipes, I think the Jetex/ Simons exhausts are OK, but you can get equally good results with parts from the scrapyard. I'm absolutely not an expert, but I learnt a lot about airflow in engines and porting from David Vizard's book "How to port & flow test cylinder heads".

quote:

Originally posted by AnttiK

Sorry for mixing these other things to your injection topic

No worries, forum threads are public domain, and you've been mixing in very interesting stuff anyway!

quote:

Originally posted by AnttiK

I think modifying the 2.9 intake manifold is a good idea and final result depends how the welding is succeeded.

I'm not going to attempt the welding myself, better to leave it to someone who knows what they're doing, there'll be other opportunities to learn TIG welding aluminium.

www.saabv4.com |  |

|

AnttiK

V4 Fan

Finland

103 Posts |  Posted - 22 May 2020 : 12:37:19 Posted - 22 May 2020 : 12:37:19

| quote:

Originally posted by melle

I'm not going to attempt the welding myself, better to leave it to someone who knows what they're doing, there'll be other opportunities to learn TIG welding aluminium.

Yes, I mean that it might be some kind of challenge even for professional welder, but as you have described in first post the proper work preparation with the welding jig (engine) before welding will help in that.

I was looking at the two fixing bolts between engine block and manifold in the front area of manifold. Aren't those closer to each other in V4 manifold (near the thermostat housing) than in V6? And in V6 the intake runners are pretty close to those bolt holes, so it needs to be considered. |  |

|

UK_Sub

V4 Guru

United Kingdom

2558 Posts | |

Topic Topic  | |